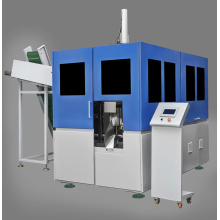

Semi-Automatic Water Bottle Blowing Machine

Product Description

Semi-Automatic PET bottle blowing machine

1.Semi-Automatic machine

2.Blow Capacity:1200-1600bph

3.Mitsubishi PLC

4.CE,ISO,SGS

Introducton:

Semi-automatic blow molding machinery is suitable for producing PET plastic containers and bottles. It is widely used to produce the carbonated bottle ,mineral water,carbonated drink bottle, pesticide bottle oil bottle cosmetics,wide-mouth bottle etc.

Adopting double crank to adjust mould ,heavy locking mould, stable and fast ,Adopt infrared oven to heat the perform ,the perform rotated and heated equally.

The air system has been divided into two parts: pneumatic action part and bottle blow part to meet the different requirements for the action and blow .It can provide sufficient and steady high pressure for blowing large irregular shaped bottles.

The machine is also equipped with muffler and oiling system to lubricate the mechanical part of the machine.

The machine can be operated in the step-by-step mode and the semi-auto mode.

The machine is small with low investment, easy and safe to operate .

Function:

1. Controlled by MITSUBISHI touch screen computer. Operate consistently and simply.

2. Pneumatic elements from FESTO (German) and SMC (Japan)

3. Energy-saving and environmentally friendly design. Mechanical units are compact and rational.

4. Malfunction alert and diagnostic units allow easy maintenance.

5. Suitable for manufacturing a variety of PET bottles: mineral water bottles, edible oil bottles, soda bottles, medicine bottle, cosmetics bottles etc..

6. Oven can be made according the different preform requirements of customers

Main Parameters:

Container | Product material | PET |

Volume | 0.1L-2L | |

Theoretical output | 1200-1600PCS/H | |

Preform length | 15mm-350mm | |

Preform inner diameter | φ5mm-38mm | |

Moulding | Max.mould plate Dimenstion(L x W) | 350x380mm |

Max.mould thickness | 180mm | |

Clamping force | 45KN | |

Mould opening stroke | 160mm | |

Machine size and weight | Main machine (L x W x H) | 160x60x161KM |

Main machine weight | 500Kg | |

Heater (L x W x H) | 187x63x145KM | |

Heater weight | 250Kg | |

Power | 17.5kw |

Container | Product material | PET |

Volume | 0.1L-2L | |

Theoretical output | 1200-1600PCS/H | |

Preform length | 15mm-350mm | |

Preform inner diameter | φ5mm-38mm | |

Moulding | Max.mould plate Dimenstion(L x W) | 350x380mm |

Max.mould thickness | 180mm | |

Clamping force | 45KN | |

Mould opening stroke | 160mm | |

Machine size and weight | Main machine (L x W x H) | 160x60x161KM |

Main machine weight | 500Kg | |

Heater (L x W x H) | 187x63x145KM | |

Heater weight | 250Kg | |

Power | 17.5kw |

Related Products

Trade Information

| Trade Terms | EXW,FOB,CFR,CIF or others |

| MOQ | 1set |

| Port | Shanghai port |

| Shipment | Ocean or air transportation |

| Payment Terms | L/C,T/T, Western Union, MoneyGram |

| Payment condition | 30%T/T |

| Supply Capability | 1 Set/Sets per Month |

| Lead Time | About 30 days |

Cooperate Clients

Company Information

Zhangjiagang King Machine Co., Ltd,is a direct manufacturer and exporter specializing in water treatment plants, beverage Filling Machine, Packing Machine, bottle blowing machine, injection moulding machine and spare parts of filling line.

Our factory was established in the year of 1995, with the long history of accumulated experience in filling machine industry in south Jiangsu. There are many development engineer of filling machine in our company. We devote ourselves to the development, research and production of liquid food and beverage packing and filling industry.

King Machine cooperated with many customers in recent years, we win the trust of customers from our high-quality products. And we are looking forward to the future cooperation with you if our products can impress you deeply.

After Sale Service

1. We send the engineers to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the machine:

a. Machine layout

b. Electricity diagram

c. Machine certificate

d. General manual book/maintenance book

Contact us if you need more details on Bottle Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Bottle Producing Machine、Blow Molding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Blow Moulding Machine

Premium Related Products

Other Products

Hot Products

Ointment Tube Filling MachineMultipurpose Filling Machine Honey Filling Machine Cream Filling MachineHX-009 The Plastic Tubes And Plastic-Aluminum Laminated Tubes Filling And Sealing MachineHX-003 Top Sale Cosmetic Tube Ultrasonic Sealing MachineAutomatic Mask Filling Sealing MachineHorizontal Automatic Flow Hard Candy Packing MachineHengxing Semi-Automatic Shrinking Packing MachineNew Paper Card and Plastic Blister Packaging Machineryhigh frequency pvc welding machine priceHigh Speed Automatic Plastic Blister Vacuum Forming Machine for PVC/PET/PS/PE/PP, CE ApprovedCool design welding machine price for Electronic ProductsSmall Size Semi-Automatic Cosmetic Tail Plastic Tube Sealer MachinePlastic egg tray forming machine with Factory price top qualityHigh Speed Automatic Soft Tube Filling and Sealing MachineBest Price Automatic Soft Tube Filling & Sealing Machine, Toothpaste Tube Filling Machine, Cream Filling and Sealing MachineAutomatic Tube Filling Sealing Machine HX-006